-

Gallery of Images:

-

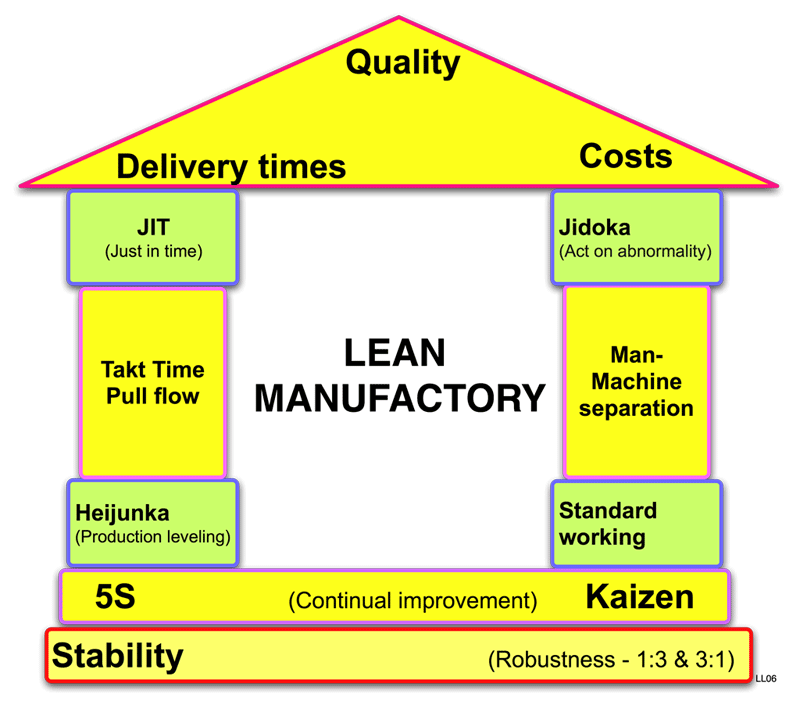

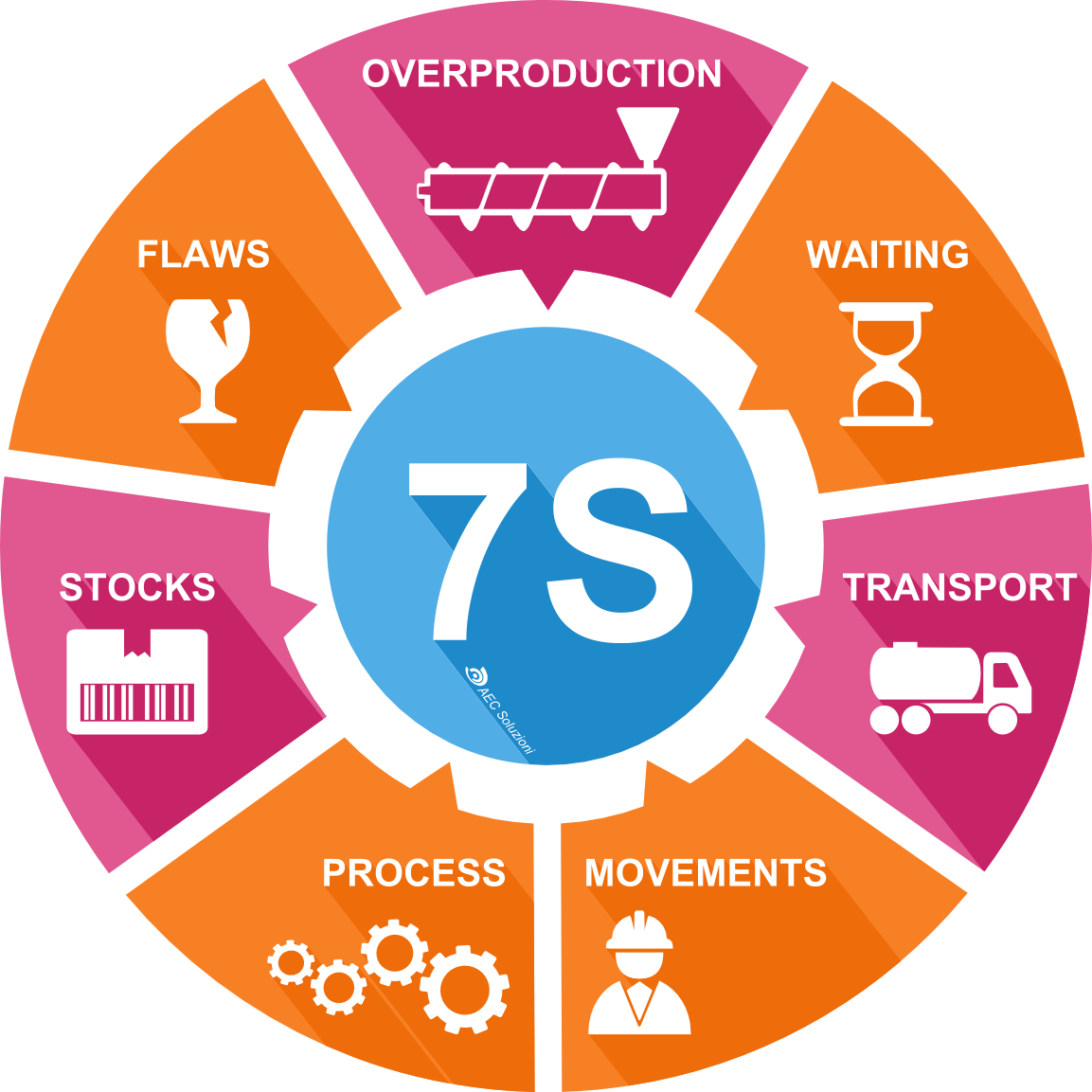

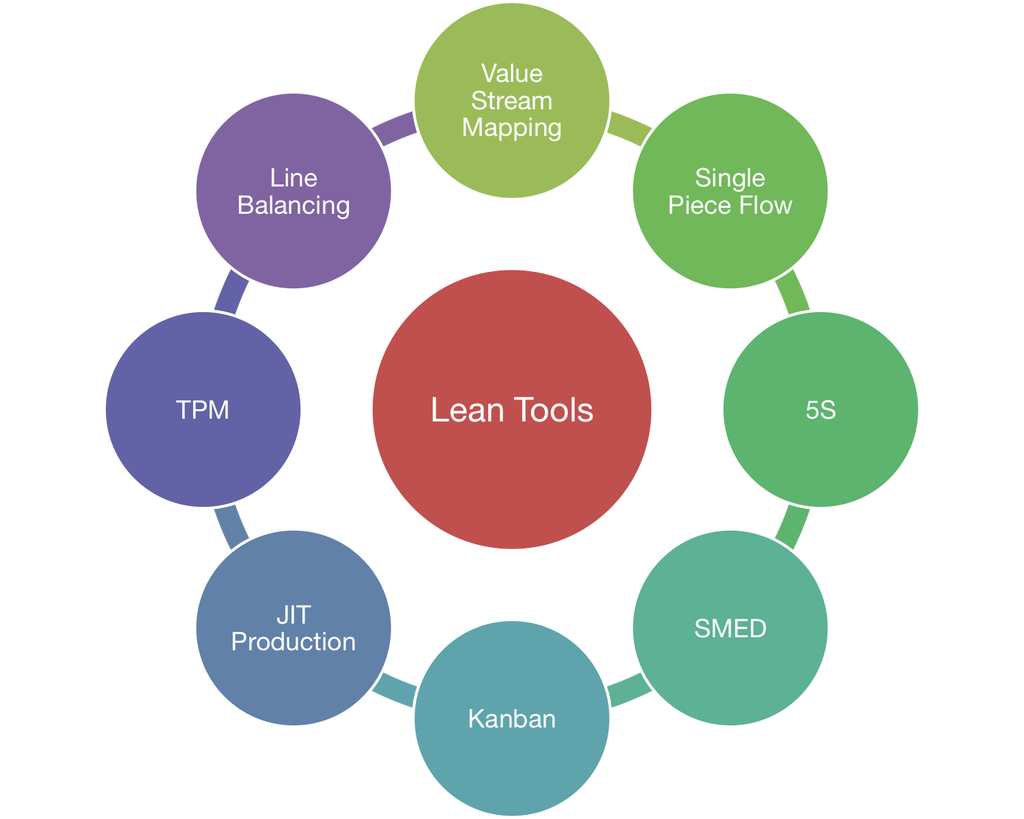

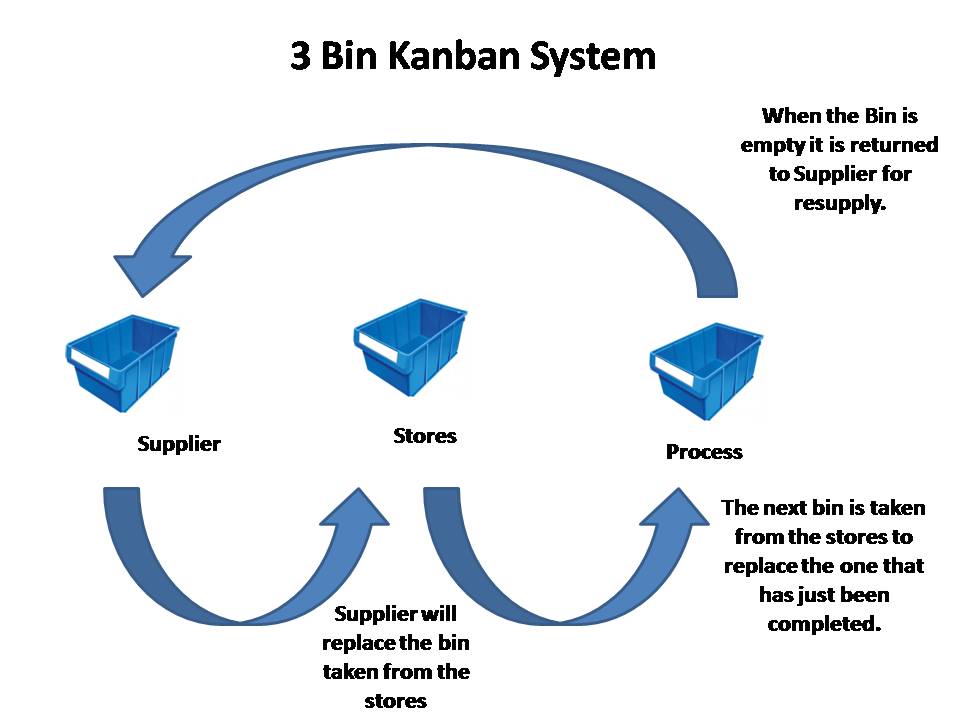

Lean Manufacturing A Powerfull Tool for Reducing Waste During the Processes Lean manufacturing provides a new management approach for many small and medium size manufacturers, especially older firms organized and managed under traditional push systems. Improvement results can Lean Manufacturing is Defined and Explained. Lean Manufacturing or Lean Production are Critical to the Success of Modern Manufacturing Systems, Lean Manufacturing Extends also into Service Industries. The primary objective of lean manufacturing is to assist manufacturers who have a desire to improve their companys operations and become more competitive through the implementation of different lean manufacturing tools and techniques. As lean thinking continues to spread to every country in the world, leaders are also adapting the tools and principles beyond manufacturing, to logistics and distribution, services, retail, healthcare, construction, maintenance, and even government. The purpose of this study is to investigate the adoption of lean manufacturing tools and techniques in the silk production Industry, A questionnaire survey was used to explore 14 key areas of lean manufacturing namely, scheduling, inventory, material handling, equipment, work processes. There are a lot of great ideas to explore in lean. One way to start is to survey the most important lean tools, with a brief description and short explanation of how each tool can improve your manufacturing operations. Free online process improvement and quality improvement toolkit and toolbox using Lean Six Sigma or 8Discipline method. Lean manufacturing is a movement established by Toyota Production Systems and is centered on clarifying what brings value by reducing waste. Lean is centered around increasing customer value and implementing key processes in order to continuously drive. Lean Manager, Packaging Manufacturer, Mitchell SD We have a variety of lean manufacturing visual boards you can buy that are already designed for you. We make it easy to purchase the professional boards that you need for your business. There is a misconception that Lean and Lean Six Sigma methodologies are only applicable to manufacturing or supply chain processes. Lean Manufacturing even impacts Six Sigma, as Lean Six Sigma has evolved into an approach taken to reduce waste, improve efficiency and drive profitability. Lean as a Tool We offer 5S Supplies, Lean Products and other 5s lean manufacturing, 5s training supplies at the best prices available on the market. The Tool Foam we purchased has transformed our organization. Due to high standards in the Aerospace Industry we have partnered with. Lean Tools The following is a collection of 25 essential lean tools. Each tool is distilled into a simple description of what it is and how it helps. In lean manufacturing, wait time is considered nonvalue added, and is a form of waste to be eliminated. In an injection molding process, valuable seconds, or even fractions of a second, of cycle time can be saved through the optimization of machine movements and timing. Lean Manufacturing Tools and Techniques With companies and manufacturing units getting upgraded to newer and more efficient practices, it becomes evident that theres a great need for manufacturing tools and techniques to improve this situation. Manufacturing is gaining momentum as the world. Lean Thinking, a concept that is based on the Toyota Production System, extends continuous improvement efforts to reduce the costs of serving customers beyond the physical boundaries of a manufacturing facility, by including the suppliers, distributors Lean Manufacturing: The latest term used to describe a philosophy of manufacturing committed to the elimination of waste from the entire value stream, and to Continuous Improvement in all things. Waste is defined as anything that does not add value from the customers perspective. A lean organization understands customer value and focuses its key processes to continuously increase it. The ultimate goal is to provide perfect value to the customer through a perfect value creation process that has zero waste. Here you'll find free, high quality Lean Tools Templates from GoLeanSixSigma. Tool Cart with support for tools, rotative component for paper sheets, drawer in galvanized sheet metal (slides with locking system) and for coupling with other structures. Implementation selected tools of Lean Manufacturing 5 1. Aim and scope of the project The aim of the project is the implementation of manufacturing tools to improve the Our Lean manufacturing tools are exactly what youll need to get started. LabelTac printers and supply comes in a variety of sizes and colors, perfect for 5S color coding, labeling tool storage systems, GHS, Six Sigma, and much more. Lean Manufacturing works best with suppliers that deliver high quality components precisely when they are needed. Supplier development attempts to locate or train suppliers to do so and develop a network of competent suppliers. Ergonomics As a Lean Manufacturing Tool for Improvements in a Manufacturing Company Prof. Rosnah Mohd Yusuff Department of Mechanical and Manufacturing Engineering, Faculty of Engineering, University Putra Malaysia rosnahmy@upm. my Nor Suhada Abdullah Brief Definitions of Lean Manufacturing Tools Methods Used In Production and Manufacturing Process Improvements Under the System of Lean Manufacturing. This tool allows you to reduce inventory, decrease leadtimes, and produce the variety of products your customers want, as they want them. Lean provides tools and processes to eliminate waste from the manufacturing process resulting in improved efficiency, effectiveness, and profitability. This article explains the philosophy of LEAN Manufacturing in a practical way. After reading you will understand the basics of this powerful quality management tool. LEAN Manufacturing or LEAN Management originates from the Japanese car manufacturer Toyota. LEAN Manufacturing literally means lean production. As a lean tool, 5S is used in many industries, including manufacturing, software, and healthcare. It can be one of the easiest lean tools to start with, and it can be used with Kaizen and Kanban to create the most efficient workplace possible. Kamishibai is a simple lean tool that can be used to improve any aspect of a business or process. Kamishibai means paper theater and was originally used by parents in Japan as a story time for. Lean presentation ppt 189, 661 views. Follow s lean tool set Dell has annual improvement; Strategies for optimizing asset performance Financial value generated or enabled by physical assets. Physical assets industrial facilities, manufacturing facilities, and equipment In stead of demanding financial. The challenge is the lean implementation, he explains training the workforce so they understand lean principles, developing a culture that is open to change and problemsolving. Those are what is most important, he says, not the tool. Lean manufacturing is a core principle to this end, but like Toyota and Prof. Netland, I firmly believe Industry 4. 0 isnt here to replace or supplant the lean manufacturing methodology, but rather to inform and complement the automotive manufacturing process, providing the data, intelligence and insight needed to aid in decisionmaking. The scheme Correct Arrangement of the Tool from a CIT instruction sheet, . Although the origins of the 5S methodology are in manufacturing, it can also be applied to knowledge software, or media in the place of physical product. 5S in lean product process development. The output of engineering and design in a lean. Tool board Lean Enterprise Tool organization Operational excellence Lean Manufacturing Welding shop Lean Six Sigma Statistics Workplace Moving Out Log Projects Atelier Forward Shadow boards, tool boards at for Seiton and create the foundation for all other Lean tools and pillars to sustain. Lean Manufacturing Tools shows what the various lean tools are and how to implement them within the philosophy of Lean Manufacturing. This includes ideas such as Just in Time (JIT), 5S, Kanban, and SMED to name just a few. Lean manufacturing is a system that aims to eliminate waste, improve quality, and increase profits by creating value based on customer needs. Businesses gain the greatest benefit from 5S when it is used with other lean tools. Steel Industry and Lean Manufacturing: See Metal Producers and the article Running Steel Lean Stockroom Location Systems: There are many methods for deciding where to put parts within a stockroom, and there are plusses minuses for each. This tool also can be a part of a Kaizen cycle, incorporated within the Analyze and Improve phases. An example of how the For processes involving cycle times, such as manufacturing or incident management, the asis cycle time can be captured in the Measure phase. I just finished reading a book by Micheal L. At Technicut Tool, we implement the 5s standard methodology to maximize spatial effectiveness. In doing so, we create an environment that promotes organization, cleanliness, and efficiency in order to actualize potential productivity. Lean manufacturing or lean production, often simply lean, is a systematic method for waste minimization (Muda) within a manufacturing system without sacrificing productivity. Lean also takes into account waste created through overburden ( Muri ). Lean Six Sigma tools and templates for implementing Lean Six Sigma in your business or organization. This includes Six Sigma tools like control charts, SIPOC and others. Lean manufacturing is an implementation of the lean methodology, which focuses on eliminating waste within a system. It is often simply referred to as lean, and while manufacturing is the most common area where this methodology is used, it can also be implemented in a wide range of industries. LeanTool Tools for lean Stopwatch 100 Laps Cycle Stopwatch 100 Laps Cycle is a tool to observe Cycle Time directly from Your Notebook Netbook With this tool, You can observe Cycle Time and make graph for the result automatically. height 635 width 1133 originaldate 6: 00: 00 AM Standardized Work Combination Table Macro Create. Lean Manufacturing: Principles, Tools, and Methods 1 6 Bosch Rexroth Corporation A smooth, uninterrupted flow of completed workpieces is the desired result of a properly designed lean workcell. Lean production or lean manufacturing is a systematic method for the elimination of wastes within a manufacturing process. This may include wastes created through unevenness in work loads, overburden and any work that does not add value. Lean tool are helpful to indentify the waste and non value added thing in system and provide the tool for removing the wastes. Waste is reduced by the lean technique in XYZ manufacturing company; there is manufacturing work, the loder backhoe, vibratory compactor. Every company has a different focus for lean initiatives, but successful strategies all depend on data. CribMaster can provide actionable intelligence. Lean Manufacturing PDF to download for free! Start to use Lean Manufacturing PDF that works. Takt Time is the base to evaluate bottlenecks. Calculate always on line and receive in your mailbox. Lean Manufacturing or Lean Production is a long journey and. Creating a great looking tool shadow board wasnt exactly written into your contract now was it! Experts in Effective Lean Manufacturing Open Los Angeles Division. Leaders in lean manufacturing solutions, Lean 5S Products, announce their expansion to a new Read More. An important question to consider when.

-

Related Images: